This is not a technique I've perfected, but I think it has some interesting applications and I haven't seen anyone else write about it.

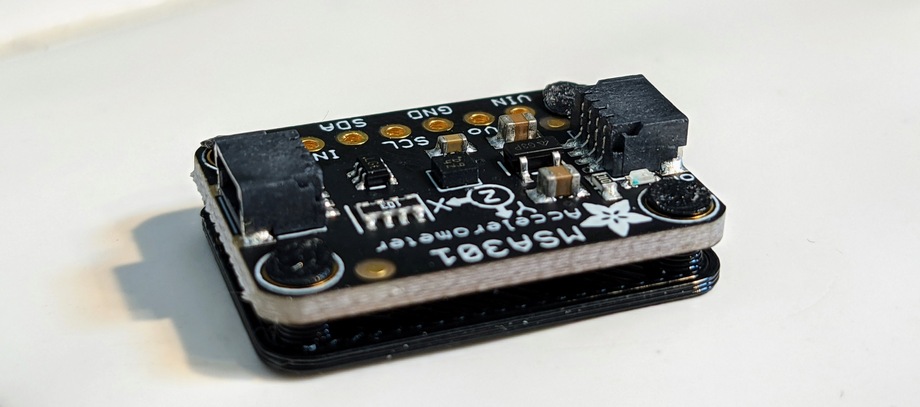

I frequently design 3D prints that include PCBs. Common techniques for retaining PCBs in 3D prints include screws and clips. Clips can interfere with access to PCB pins/headers, while screws need, well, screws and sometimes nuts or threaded inserts.

While contemplating this problem, I was reminded of the construction of common tactile switches. A small metal plate is retained by little plasic blobs at each corner. Presumably, the blobs were originally part of the main molded plastic switch body, and the manufacturing process first placed the metal plate and then melted the plastic. This process seems to be called "heat staking" or "thermal staking".

The main downside of heat staking is that you can't remove the PCB without destroying the print. Ouch.

There are various staking processes. This source shows some possible geometries. Unfortunately, I don't have the special concave tools required. However, knowing suggested geometries is helpful! For instance, given a hole of diameter 'd', a boss that is initially 1.6d above the surface to bond should flatten to a diameter of 2d and a height of .5d, at least using a flared stake tool with the right geometry.

I don't have a special tool, but I do have some nice broad flat tips for my iron: these heat set insert tips. Unfortunately, the inexpensive iron I use with them can only be adjusted down to 280C and I am pretty sure that's just a power setting, not a temperature setting. Melting PETG even at the "280C" setting seems to release some pretty nasty fumes, I don't recommend it.

There's also the problem of the plastic sticking/melting onto the tip. To mitigate this, I use a piece of polyimide (often called by the brand name Kapton) tape between the iron and the plastic. The same piece of tape can be moved & re-used multiple times.

My procedure:

- Design the bosses into the 3D printed part

- Print. My test pieces have been in PETG plastic.

- Place the PCB on the bosses

- Put polyimide tape over a boss

- Heat my iron for a bit, turn it off, then press the tip down onto the tape to melt the boss

- Repeat the last two steps for each stake

I don't know how much further I'll pursue this technique, but it's a good one to have in the toolbox!

Entry first conceived on 3 February 2021, 14:20 UTC, last modified on 3 February 2021, 16:50 UTC

Website Copyright © 2004-2024 Jeff Epler