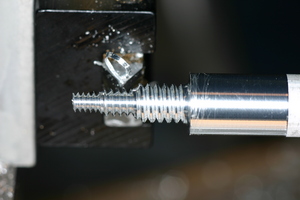

These photos show 4 threads with different four diameters and pitches (6-32,

10-24, ¾-20, and ⅜-16—those are the four nuts we found) being cut with emc.

The program takes advantage of the new

constant

surface speed and feed per revolution features when facing, turning, and

parting. (It may also use CSS when threading, but I'm not sure) This really

seem to improve the chip and finish. As before, the lathe is Chris's sherline

retrofit with servo motors,

2-axis l298 servo amplifier,

and

pluto-p servo controller.

Other work has included bugfixes to the classicladder and motenc drivers

which had crept in and prevented toolchanges on the mazak from taking place.

(originally posted on the AXIS blog)

Entry first conceived on 13 June 2007, 3:14 UTC, last modified on 15 January 2012, 3:46 UTC

Website Copyright © 2004-2024 Jeff Epler